Removal of Coating & Paint with Laser

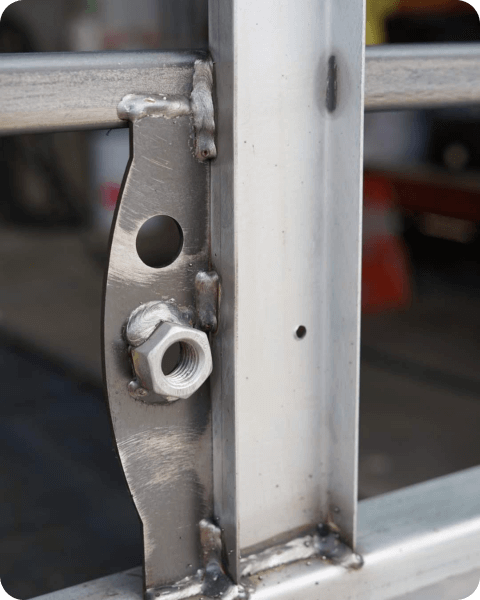

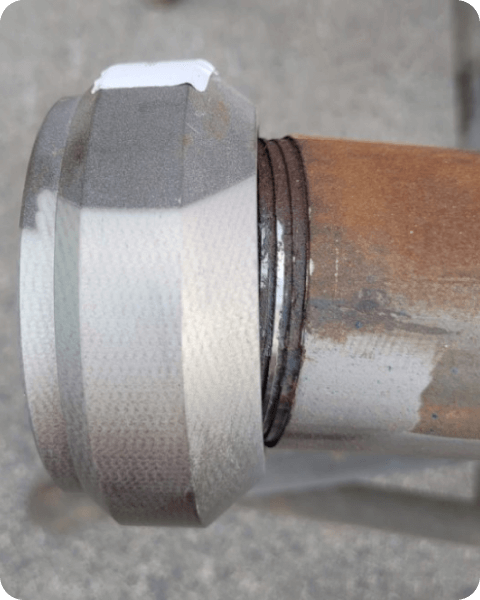

Selectively remove coatings and protective layers. The process is dustless and particulars are captured with our extraction systems.

Project Laser can selectively and precisely remove coatings, paint and residues from ferrous and non-ferrous metals, wood, masonry and more. Laser cleaning for the removal of coatings eliminates the use of abrasives and chemicals making it a good solution for localised coating removal onsite and in situ. potentially eliminating costly encapsulation and disposal of blast media.

Some of the coatings that can be selectively removed with laser technology include:

- Anti corrosion coatings

- Lead based paint

- Protective layers

- High build epoxy

- Paint

- Anodizing

- Phosphate coatings