How Laser Cleaning Works?

Project Laser was established in 2019 as a West Australian owned and operated company with the aim and providing the best quality service in this growing and exciting industry.

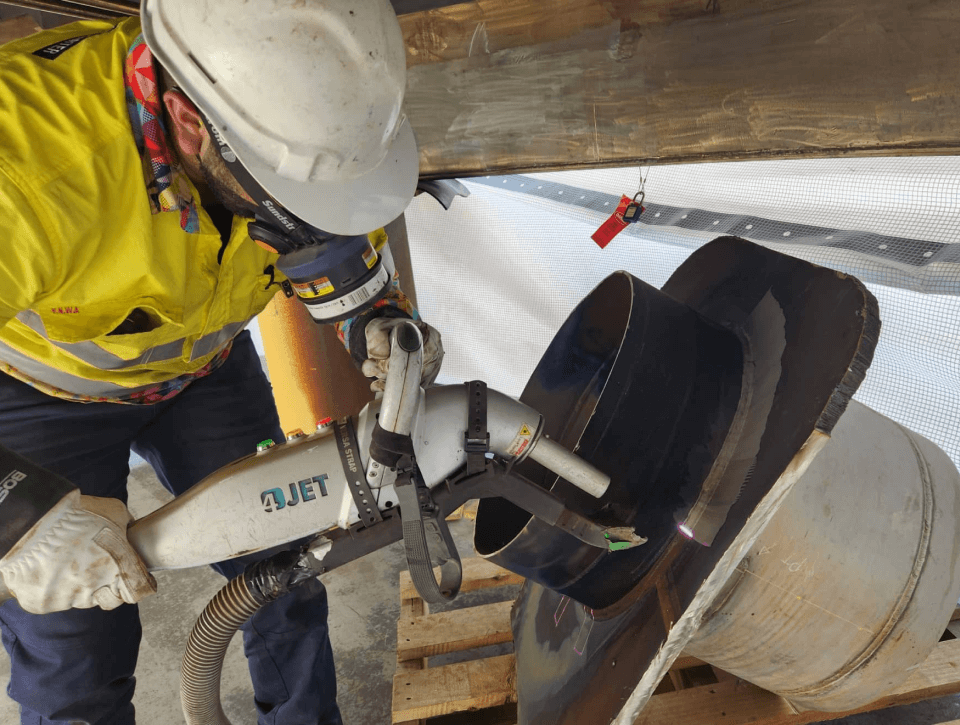

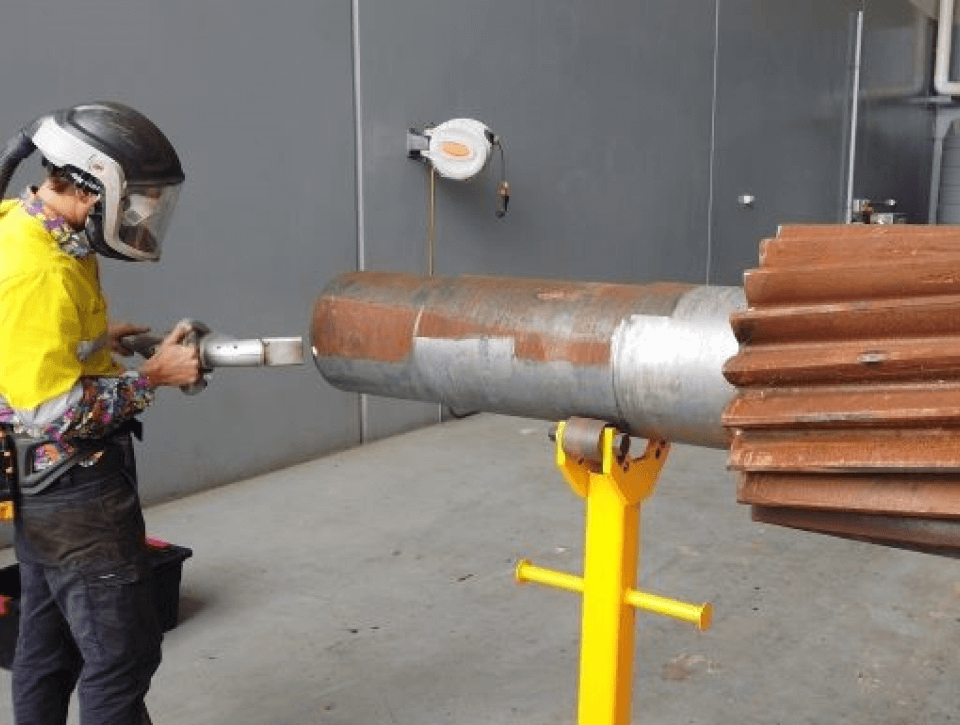

Since then we have grown to a well respected and market-leading laser cleaning company using the world-renowned and respected 4Jet laser cleaning technology.

We are the Australasian agent for 4Jet, showcasing their technology around the world and have spoken at global photonics events about laser cleaning.

View our services